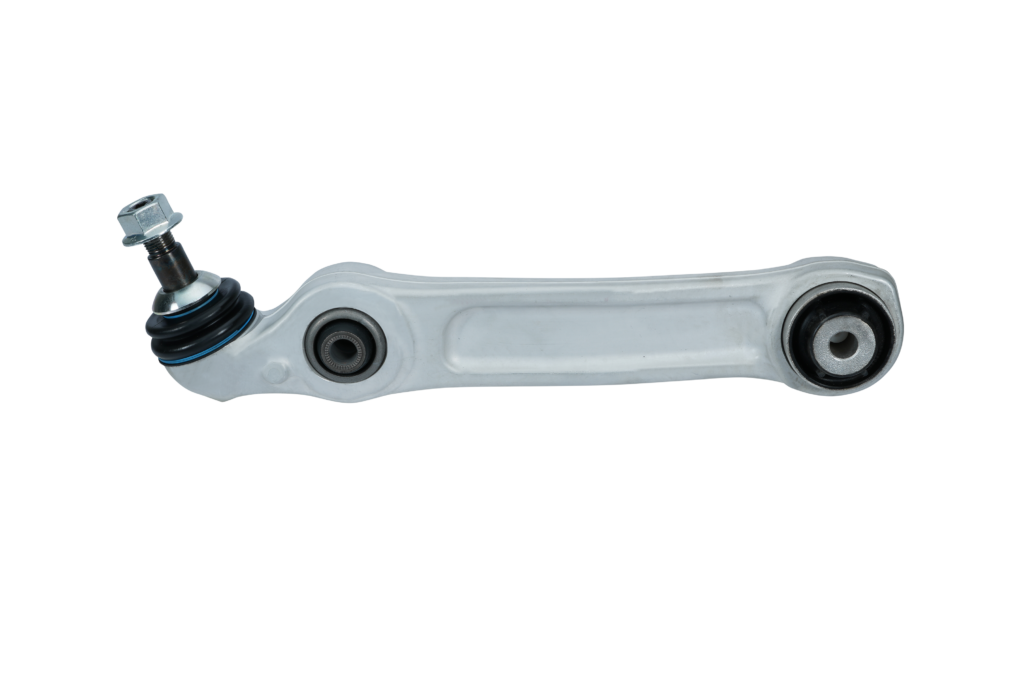

Why are aluminum control arms gaining attention in the automotive industry? Join us as we delve into the world of aluminum control arms, examining their unique features and the benefits they bring to modern vehicles.

The Rise of Aluminum Control Arms in the Automotive Industry

The automotive industry has developed for over 100 years, and vehicles, nowadays, no longer solely pursue performance but also focus more on energy efficiency, comfort and so on. To achieve this, many manufacturers have researched chassis control arms. One improved method is using aluminum alloy as the primary material for control arms.

Aluminum alloy not only reduces unsprung mass1 but also improves fuel efficiency. Aluminum alloy control arms provide an effective approach to vehicle weight reduction and bring about significant performance enhancements. However, compared to steel, aluminum alloy has its limitations. We will discuss the features and various advantages of aluminum alloy control arms in a simple and understandable way and analyze their potential applications in the future.

What Are the Essential Requirements of a Control Arm?

Control arms are crucial components of a vehicle’s suspension system, playing a vital role in ensuring a smooth, safe, and comfortable ride. Before delving into the world of aluminum control arms, in this section, we will first explore the key factors that engineers and manufacturers must consider when selecting materials and designing control arms for modern automobiles.

Mass Production

The current global annual sales of automobiles are approximately 20 million, requiring an average production of 55,000 cars per day. Therefore, if a material cannot be produced in large quantities, it cannot be considered as a material for control arms.

Sufficiently Robust

Should not easily deform by any forces. Material properties such as strength, hardness, tensile strength, toughness, ductility, etc., all need to be concerned.

Lifespan

The typical lifespan of control arms is around 8 years, during which they should not exhibit significant functional degradation.

Reasonable Price

Considering cost and customer acceptance.

Manufacturing Difficulty

If a control arm requires multiple processing steps during manufacturing, it can lead to a rapid increase in costs.

Environmental Resistance

Must withstand extreme environments, including resistance to corrosion, acids, alkalis, snow, etc., without damage.

Benefits of Aluminum Control Arms

Materials that fit the above requirements are not commonly found. Therefore, the majority of global car manufacturers currently use steel and aluminum alloy as the primary materials for control arms. Aluminum alloy is used in automobiles for two crucial reasons: its potential for lightweight construction and its contribution to enhanced passenger comfort.

Lightweight Construction

Aluminum alloy control arms integrate the characteristics mentioned above, also emphasizing lightweight construction. The ability to control weight with a certain level of strength makes them favored by car manufacturers. Aluminum alloy control arms not only reduce the overall vehicle weight but also contribute to a reduction in unsprung mass. Understanding the significance of unsprung mass far exceeds that of sprung mass.

Unsprung mass affects the wheel’s response speed, thereby not only enhancing fuel efficiency but also improving handling (, and safety). In addition, due to its structure, the aluminum alloy exhibits superior corrosion resistance compared to steel.

Passenger Comfort

Aluminum alloy is softer than steel, providing a more comfortable experience for passengers. The cost of aluminum alloy control arms is several times higher than that of steel, which becomes the biggest drawback of aluminum alloy control arms.

Aluminum Control Arms vs Steel Control Arms

It has been repeatedly mentioned above that the advantage of aluminum alloy control arms lies in lightweight construction. Specifically, how much weight can it reduce? Let’s delve into the intrinsic understanding of the differences between aluminum alloy and steel by observing the material and mechanical properties of aluminum and steel. The data quoted here is not from the very real materials used, so the values may vary slightly. However, we will focus on the comparison between aluminum and steel, so we can temporarily overlook the minor differences from the actual materials used.

| Steel | Aluminum | |

| Density(g/cc) | 7.8 | 2.7 |

| Cost (USD) | 700 | 2500 |

| Young’s modulus (GPa) | 200 | 68 |

| Yield Strength (MPa) | 350 | 270 |

| Elongation (%) | 15 | 12 |

Next, let’s analyze the information from the chart to understand the differences involved.

Density

Density fundamentally determines the mass of the material. A lower density means a lighter weight for the same volume. Comparing aluminum with a density of 2.7 (g/cc) to steel, which is essentially three times heavier with a density of 7.8 g/cc, we can confidently say that aluminum outperforms steel in terms of lightweight construction.

Cost

The cost of aluminum alloy is approximately four times that of steel, which is why aluminum alloy control arms are often used in high-end vehicles to offset the higher cost.

Young’s Modulus

The specific calculations are more complex, but here we only need to know that a smaller numerical value indicates a softer feel. Therefore, aluminum alloy control arms are more comfortable than steel control arms.

Yield Strength

The strength of aluminum alloy is not as high as steel, as shown in the table with 350 vs. 270. Therefore, we can conclude that aluminum alloy control arms are more prone to deformation. However, after T6 heat treatment aluminum. After this treatment, the strength can reach above 300 MPa.

From the above information, we can confidently say that aluminum alloy control arms are indeed superior to steel control arms. However, the significant material cost is a challenge that manufacturers must face. Currently, in the market, most vehicles are not equipped with aluminum alloy control arms. The commonly used aluminum alloy control arms are usually made of 6061 with T6 heat treatment processing. Some high-end supercars may opt for 6110 with T6 processing to achieve a strength exceeding 400 MPa.

Application of Aluminum Control Arm

The weight of control arms can have a significant impact on the chassis response, especially in vehicles with multi-link suspensions. Due to the higher number of control arms compared to other suspension forms, choosing steel material at this point would undoubtedly burden the vehicle.

Next, we will explore the application of aluminum alloy control arms in real cars.

BMW 7 SERIES G11/G12 (2015-2021)

Front Three-Link Suspension: 3 aluminum alloy control arms.

Rear Four-Link Suspension: 3 steel control arms and 1 aluminum alloy control arm.

The three pictures above show the front control arms of the BMW 7 Series G11. As you can see, they are all made of aluminum. The 7 Series is BMW’s flagship model, with an MSRP over $90,000 USD. The use of all-aluminum control arms demonstrates the high cost and the meticulous attention to detail given to their flagship model.

M-BENZ S-CLASS W222 (2013-2020)

Front Three-Link Suspension: 3 aluminum alloy control arms.

Rear Four-Link Suspension: 4 aluminum alloy control arms.

From the flagship sedans of two German brands, we can understand that aluminum alloy control arms can be mixed with steel control arms, once again demonstrating the high cost of aluminum alloy.

Future of Aluminum Control Arm

Even though aluminum alloy control arms have significant advantages, the heavy cost still prevents them from becoming mainstream in the market. However, in an era where electric vehicles are becoming more prevalent, the weight of heavy batteries may force car manufacturers to use more aluminum alloy control arms.

References

- TGQ R&D

- Chassis Handbook Bernd Heißing, Metin Ersoy (2010)

Related articles:

Components of Suspension System: What are the Functions?

6 Symptoms of Bad Control Arm: Causes, Prevention & Solutions

What is Double Wishbone Car Suspension? Mechanics Explained!

- Unsprung mass: Depending on the design of the vehicle model, the range of unsprung mass may vary slightly. Nevertheless, control arms are generally considered as semi-unsprung mass. ↩︎