Whenever people talk about automotive chassis or suspension, the first components that come to mind are often shock absorbers and struts—and that’s usually as far as the thought goes.

However, when it comes to cars, is it simply because these two parts are overly famous? (Thanks to the obsession many car enthusiasts have with modifying shock absorbers, and abundance of aftermarket brands available.) As a result, people tend to overlook other components of the chassis, which brings us to today’s topic: ball joints and tie rods.

Some motorists use the terms ‘ball joints’ and ‘tie rods’ interchangeably, and even some car mechanics find it hard to tell them apart. While they understand that tie rods and ball joints are not the same, pinpointing their differences can still be a challenge

In fact, ball joints and tie rods are entirely different and serve distinct roles. For example, they can be compared to a keyboard and a USB connection. The keyboard uses the USB connector to link to the computer for input. While both are peripheral devices, they shouldn’t be discussed as equals. Additionally, without ball joints and tie rods, your car wouldn’t even be able to turn!

Whether you’re an automotive enthusiast, a car mechanic, or simply someone who wants to avoid being misled by mechanics and losing hundreds of bucks, this article will dive deep into ball joints and tie rods, exploring what they are and how they work.

1 Why do people confuse tie rods and ball joints?

Nowadays, all passenger vehicles are equipped with suspension and steering systems. The suspension system ensures the vehicle runs smoothly over uneven roads, while the steering system allows it to turn. Both systems consist of various components but are located in the same area within the car. Additionally, ball joints and tie rods are part of these systems, which explains why people often confuse them.

Secondly, people often overcomplicate the concept of ball joints. Let’s simplify it. When you hear the word “joint,” what comes to mind? Most would probably think of their own joints or those of animals—flexible, capable of moving freely at various angles.

In the same way, a ball joint serves a similar function. It’s not a single, specific part but rather refers to a device that enables rotational movement in 360 degrees and tilting in multiple directions. Its name is derived from the spherical structure inside this flexible mechanism. Essentially, a ball joint functions just like a joint in the human body.

2 Different between ball joint and tie rod in brief

The biggest difference between ball joints and tie rods is that they shouldn’t be regarded as components to be discussed together.

Ball joint

A ball joint is a mechanical component widely used in daily life, providing flexibility and rotational movement. It can be incorporated into various devices wherever such movement is required.

Tie rod

Tie rod is an automotive component used for turning vehicles. It falls under the classification: Automotive > Chassis System > Steering System > Tie Rod. Additionally, the tie rod includes a ball joint mechanism within its structure.

3 What is tie rod

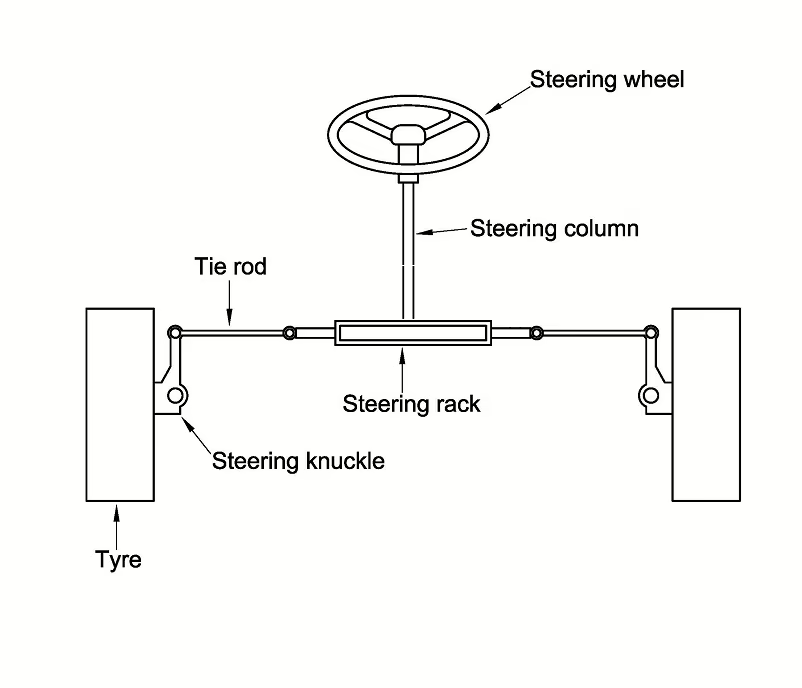

As mentioned in the previous passage, the tie rod is part of the steering system. It is a rod, typically around 20 inches in length, that connects the wheel carrier (steering knuckle) to the steering rack.

When we turn the steering wheel, it connects through the steering column to the steering gearbox and then pushes the steering knuckle via the tie rod to enable turning. In other words, the tie rod’s lateral movement determines the direction of the turn. During this process, the wheels rotate around the kingpin axis as their center.

The tie rod is connected at one end to the steering rack, which uses a gear system to allow the tie rod to move laterally. The other end of the tie rod connects to the steering knuckle, which is where the wheels are mounted. As the tie rod moves, the wheels also move accordingly, allowing the car to turn. Additionally, since the tie rod is connected to the wheel carrier (or steering knuckle), and the wheels move up and down due to road surface variations, the tie rod also contains a mechanism that enables it to adapt to the vertical motion of the wheels, while still controlling their lateral movement.

Other names for tie rods

- Tie rod

- Tie rod assy

- Tie rod assembly

- Side rod

- Side rod assy

- Side rod assembly

4 Components of tie rod

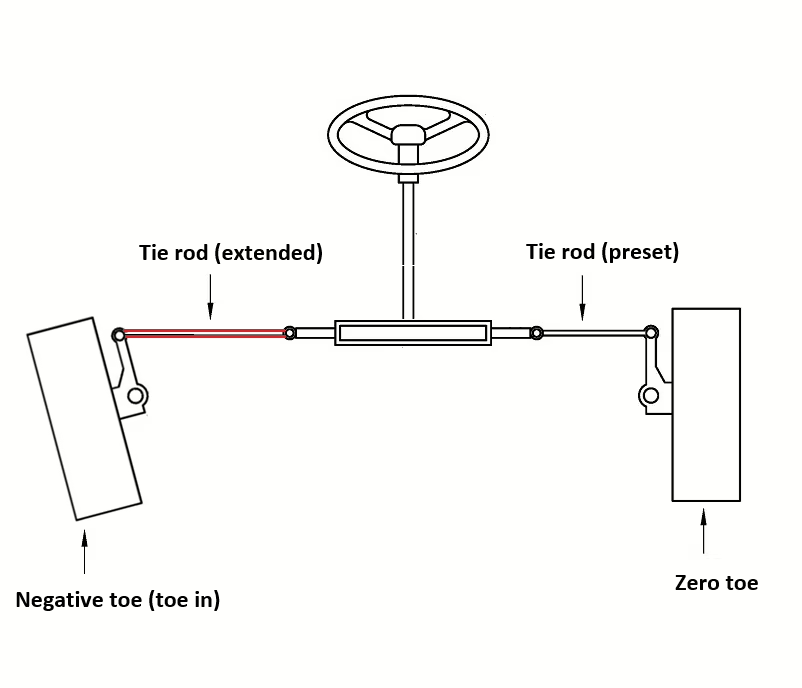

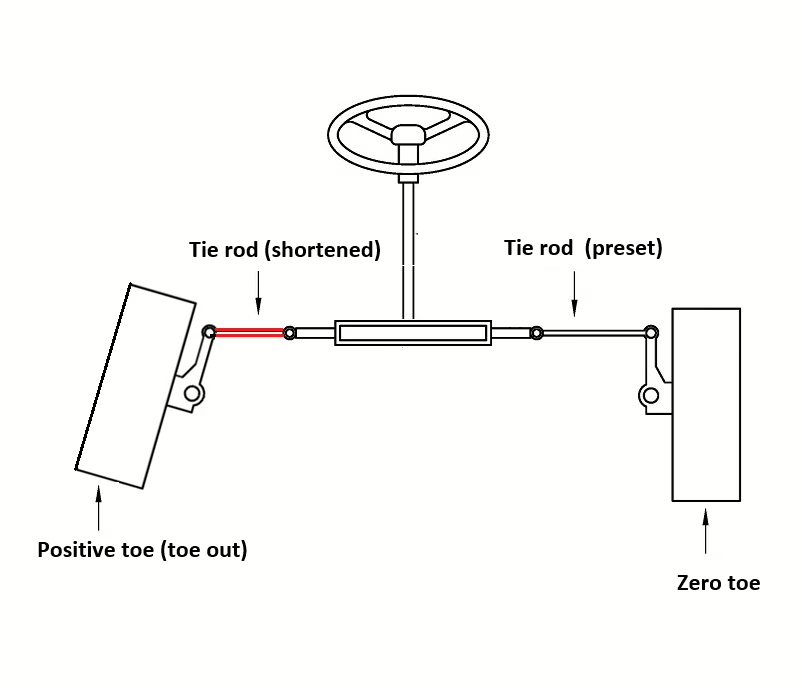

From the earlier part, we understand that a tie rod is also called a tie rod assembly. This means that tie rods are not a single part; they are actually composed of two components: the rack end and the tie rod end. These two parts are connected by a threaded mechanism and secured with a lock nut, which allows for the adjustment of the tie rod’s length.

According to the structural diagram, when the length of the tie rod changes, the tire’s toe angle also changes. Additionally, in modern sedans, toe is the only adjustable angle during alignment. In principle, when performing a wheel alignment, the left and right tie rods need to be adjusted equally. However, in vehicles with dependent suspension, there is only one tie rod. That said, dependent front suspensions have almost disappeared, meaning that modern cars usually have two tie rods.

After introducing the tie rod, let’s move on to its individual components: the tie rod end and the rack end.

4-1 Rack end

One end of the rack end is connected to the steering rack, which is why it’s called a rack end. The other end features an external threaded structure that connects to the tie rod end. Inside the rack end is a ball stud, installed parallel to the rack end itself. This design allows the rack end to move up and down with the wheel without damaging the steering rack.

It is worth noting that the ball stud in the rack end must be designed to handle significant force, as the rack end endures tremendous pressure whenever the steering wheel is turned, even when turning the wheel while parking. At the same time, the ball stud’s tilt torque needs to be kept very low, so that the rack end can smoothly move up and down with the wheel.

4-2 Tie rod end

The tie rod end contains a ball joint structure and is connected to the wheel carrier, allowing it to drive the movement of the wheel carrier. On the other side, it has internal threads to connect with the rack end and uses a lock nut to adjust the toe. The design of the tie rod end enables rotation and tilt within a limited range of angles.

When the tie rod end operates, both rotation and tilt occur, which in turn pushes the wheel knuckle and enables the car to turn. The tilt angle of the tie rod end is specifically designed, and according to experience, most angles can exceed 50 degrees. Additionally, the ball joint of the tie rod end is often installed facing downward. This design helps prevent water and dirt from contaminating the ball joint.

5 BALL JOINT

Ball joint is a mechanical component and does not refer to a single, specific part. Ball joints can be applied in various devices and systems. In automotive applications, there are three major components that utilize ball joint mechanisms.

- Sway bar link

- Control arm

- Tie rod

These parts belong to the chassis system, and as such, they need to ensure that the vehicle can move vertically and make turns. Conveniently, the ball joint is a device capable of multi-directional movement, which is why these chassis components are equipped with ball joint mechanisms.

Therefore, simply mentioning “ball joint” is actually imprecise because the term alone does not indicate whether you’re referring to the ball joint in the control arm, sway bar link, or tie rod. Nonetheless, by convention, when mechanics mention “ball joint,” about 80% of the time they are referring to the control arm ball joint.

There are two main reasons for this: First, in many car models (especially Japanese cars), the control arm ball joint can be removed and replaced independently. Secondly, the ball joints in sway bar links and tie rods cannot be replaced separately; instead, the entire assembly must be changed. Additionally, each of these ball joint—control arm, sway bar link, and tie rod—has its own unique characteristics.

6 When should I replace tie rod and ball joint

Based on repair experience and chassis design perspectives, only two parts of the tie rod are prone to damage: the tie rod end ball joint and the rack end ball joint. Therefore, in the next paragraph, we will focus on the failure phenomena of these ball joints and determine when they should be replaced.

Generally, tie rods are designed to last at least 60,000 miles, and any replacements beyond this mileage are considered normal. However, there are some driving tips that can help extend the lifespan of your tie rods.

1 Avoid turning the steering wheel while the vehicle remains parked. Doing so places immense tension on the tie rods, equivalent to the force exerted by the combined weight of four adults.

2 When driving on poorly conditioned roads, slow down as much as possible. For example, reducing your speed when approaching potholes or bumps can effectively minimize the impact. This is highly beneficial for the longevity of your tie rods.

7 Signs That It’s Time for a Replacement

When tie rods need replacement, the following symptoms may appear. You can refer to the list below to check the condition of your tie rods.

1 If your car cannot maintain a straight line and keeps going to one side, this is likely due to the inability to maintain the toe angle, which is essential for controlling the vehicle’s straight-line motion. The component responsible for fixing the toe angle is the tie rod. Therefore, when your vehicle struggles to stay straight, it’s important tot check your tie rods for potential issues.

2 When driving over potholes or bumps, the steering wheel is suddenly pulled to one side. This occurs because the ball joint of the tie rod has been damaged, allowing the tires to be easily affected by road condition.

3 Indirect knocking sounds or vibrations: The symptoms of tie rod damage are similar to those of a failing control arm. However, the difference lies in the fact that the sounds and sensations from a damaged tie rod are generally more subtle and less direct. For most people, distinguishing between the two can be difficult. Therefore, if you notice unusual noises coming from your chassis, it is advisable to visit a car shop for a thorough inspection of your vehicle’s chassis.

References

- TGQ R&D

- Chassis hand books bernd heibing(2011)

- 車両運動性とシャシーメカニズム 宇野高明(2022)